PRINTING POLO SHIRTS SWEATSHIRTS AND CLOTHING

Italy T-Shirt

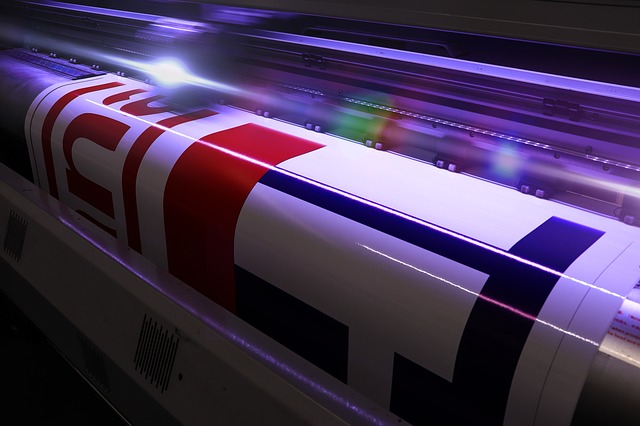

custom clothing printing

Italy T-Shirt is the brand of Tipografia Commerciale that deals with T-shirt printing and general customization of clothing and fabrics.

After many years spent in the printing of advertising and editorial paper material, in 2011 Tipografia Commerciale began a new challenge in the field of fabric customization and screen printing, giving birth to a new branch of the company that today takes the name Italy T-Shirts./h4>

The excellent results obtained and the growing satisfaction of Customers lead the company to invest in more and more cutting-edge technologies to ensure quality and fast order processing at always competitive prices.

Learn how to choose the best printing process to customize your T-shirt, polo shirt, sweatshirt, or clothing items for sports and work, too

Choosing the right technique for customizing T-shirts and clothing in general can depend on several factors. Quantity of pieces, material to be customized, type of graphic creativity to be applied. Not all methods can be compatible with every project, which is why it is necessary to rely on professionals with experience in the field who can advise on how to get the maximum product yield at the lowest cost. With Italy t-shirt today we can handle all the main printing and personalization techniques on t-shirts and fabrics in general, and thanks to the advanced technologies we use, we can print even a single piece. The wide availability of items in stock allows us to be faster and faster in the delivery of orders and to cut logistics costs.

Screen printing is the technique used in most cases for the reproduction of images on various media, but predominantly used for printing on fabric (cotton, synthetics, or blends) and especially dedicated to printing t-shirts, polo shirts and sweatshirts, bandanas, hats, etc.

Because of its application methodology, it involves making a frame for each printing color. This is also why it is more suitable for printing larger quantities in terms of print runs, so that the fixed costs of printing forms can be amortized over the quantity of pieces. These once made, can then be reused several times to reproduce the same subjects reprint designs.

Embroidery, in fabric customization, is undoubtedly one of the most refined and elegant forms. The choices of colors can be almost endless, and with modern technologies the color and graphic rendering, as well as the definition of the subject reproduced on the fabric, have reached very high levels.

Not all garments can be embroidered. In order to undergo the process they must have a certain thickness, to withstand the stresses of needle and thread of machinery, and must allow them to be worked easily on looms. In some cases, as an alternative to direct embroidery on the fabric, embroidered Patches can be created, which, again applied by stitching, also ensure a high quality output of the finished product. It can be produced on small medium and large quantities depending on the difficulty of the subject to be reproduced.

The plotters in addition to common materials can also print or carve heat-transferable media on fabrics. Production can also be of a single item. This system allows the operator to produce in small quantities without the need to set up a screen printing plant although it requires precise manual operations and produces considerable waste. Subjects in general should not have graphics that are too small and detailed, which can prevent them from being carved correctly and then make the final result inaccurate. Ideal for single-color or two-color work, they allow for products that are also decidedly economical.

We can customize clothing with different and special types of different materials, such as flocked with a velvety effect, or special 3D materials that are very original. With hot press technology, we can also transfer offset printed subjects for maximum reproduction quality on the highest print runs.

Direct digital printing (DTG = Direct to Garment) is used for personalization of preferably high-quality cotton clothing and combines inkjet technology and screen printing inks for fabrics. Images are printed in four-color directly onto the fabric.

Having no special planting costs, DTG allows for cost-effective production of small runs of t-shirts and customized clothing, with prints characterized by the presence of many different colors (four-color), shades or minute details.

Working well while respecting everyone at every stage of the production chain

In line with our philosophy, we have decided to walk the path of fabric customization through solid behavioral rules, equipping the company with important certifications that respect the world of labor in clothing production. All our inks are also certified, hypoallergenic and environmentally friendly.

Here are some of our major certifications.